Electrorheological (ER) fluids denote a class of materials consisting of nanometer to micrometer sized solid particles dispersed in a liquid, whose rheological (i.e., deformation and flow) properties are controllable by an external electric field. In particular, they can reversibly transform from a liquid to a solid within one hundredth of a second. While in the solid state (with the electric field applied), the strength of that solid, measured by the yield stress, is the critical parameter that governs the application potential of the ER fluid. Since their discovery some sixty years ago, there has been much effort in searching for ER fluids with high yield stress, mainly due to their applications in vibration damping, clutches, and practically all mechanical devices that involve motion transmission. In particular, the automotive applications, as a potential replacement for gears, have attracted sustained research at all the research laboratories of major automotive companies. In the late 1980s General Motors carried out a study on the application potential of ER fluids, and concluded that a major hurdle was the low yield stress of the ER fluids.

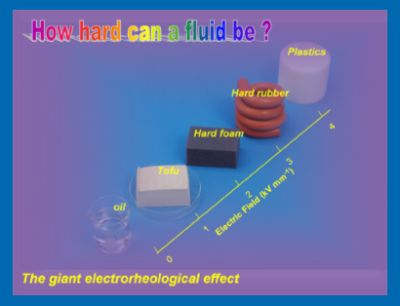

At HKUST, eight years of research work on ER fluids led to a breakthrough last year in the synthesis of a novel type of ER fluid that consists of 70-nanometer-sized coated nanoparticles dispersed in insulating oil. These new fluids, which harness the extremely high electric field that exists in Debye double layers, exhibit yield stress one order of magnitude higher than the best commercially available ER particles. The significance of this breakthrough is that the yield stress has broken the theoretical upper bound predicted on the basis of linear response of the component materials, thereby signifying a new mechanism. This new class of ER fluids is thus denoted as having a ‘Giant Electrorheological’ (GER) Effect, surpassing the threshold that the General Motors study has set for automotive applications. It is envisioned that HKUST’s GER fluids can be used not only in those classical applications, but also in micro-electromechanical systems (MEMS) or nano-EMS as replacements for microgears, reducing cost and increasing reliability and simplicity of controlled mechanical motion in the micro- to nanoscale. After its publication in Nature Materials last year, this new breakthrough has been reported around the world in the Washington Post, Science News, New Scientist, NanoToday, Nanotech, Technology Review News (TRN), and thirty other media outlets.

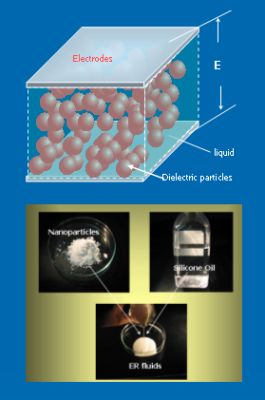

An ER (Electrorheological) fluid is a kind of colloid consisting of nanometer particles suspended in a nonconducting liquid. It can change from liquid state to solid state suddenly. (Fig.1)

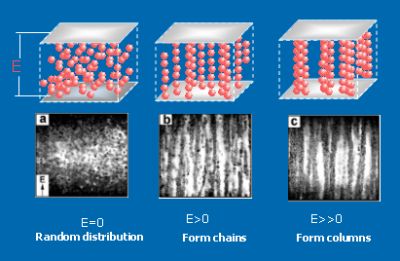

The ER effect denotes a reversible change in the apparent viscosity of a colloidal suspension under an external electric field. The unique property of ER fluids has aroused a great deal of attention in the past decades due to its potential applications. A typical ER fluid consists of solid dielectric particles dispersed in an insulating fluid, forming a two- phase colloid. (Fig. 2)

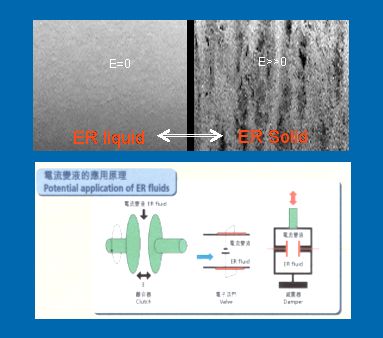

Under an applied electric field on the order of 1-2 kV/mm, the ER fluids exhibit solid-like behavior (e.g., ability to transmit shear stress). The transformation from liquid-like to solid-like behavior is relatively quick, on the order of 1-10 milliseconds, and reversible (Fig. 2). Such controllable variation of the rheological property implies a wide variety of potential applications, such as clutch or vibration damping which may be used in the next generation of automobiles. (Fig. 3)

In our previous works on ER fluids, we have synthesized several types of ER fluids with good ER performance. The most promising one involves the use of composite particles — the multiply coated microspheres with inner conducting and outer insulating layers. We observed significant enhancements in ER static yield stress compared to uncoated particles. Such type of ER fluid is called a ‘Giant ER fluid’.

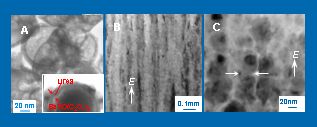

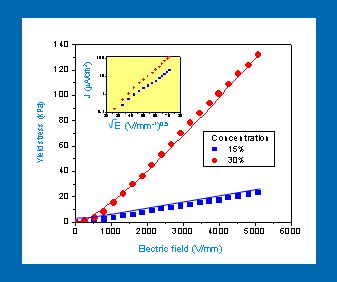

Based on our past experience on materials preparation and theoretical modeling, the scientists at HKUST started a search for a new type of ER fluid particle. The basic idea is to fabricate high dielectric particles with average diameter of 10-100 nm, which can be surface activated so that the surface ions are solvated to form electrolytic double layers (Fig. 4). Under an external electric field, the mobile ions will adjust themselves so that strong attraction between the particles is possible. After some trial and error, we have succeeded in fabricating a type of porous nanoparticle. When suspended in silicon oil, these particles exhibit relatively small yield stress. However, when surfactant is added, the yield stress increases dramatically. (Fig. 5). Its hardness is like plastics. (Fig.6)

References:

- Weijia Wen, Xianxiang Huang, Shihe Yang, Kunquan Lu and Ping Sheng, “The giant electrorheological effect in suspension of nanoparticles”, Nature Materials, 2, 727 (2003)

- Hongru Ma, Weijia Wen, Wing Yim Tam and Ping Sheng, “Dielectric electrorheological fluids: theory and experiment”, Advances in Physics, 52, 343 (2003)

- Weijia Wen, Ning Wang, Hongru Ma, Zhifang Lin, Wing Yim Tam, C.T. Chan, and Ping Sheng, “Field induced structural transition in mesocrystallites”, Phys. Rev. Lett., 82, 4248 (1999)